It was time to assemble the Lego kit I’d gotten for my birthday. It’s a Mercedes Benz ‘Arocs’ truck with a pneumatic crane. Even by technic standards this is a complex kit. The manual alone is over 400 pages!

The kit is made in five broad parts: the chassis with gears, the pneumatic crane, the cab and the bed. The gearing mechanism is dazzlingly complex and requires careful assembly.

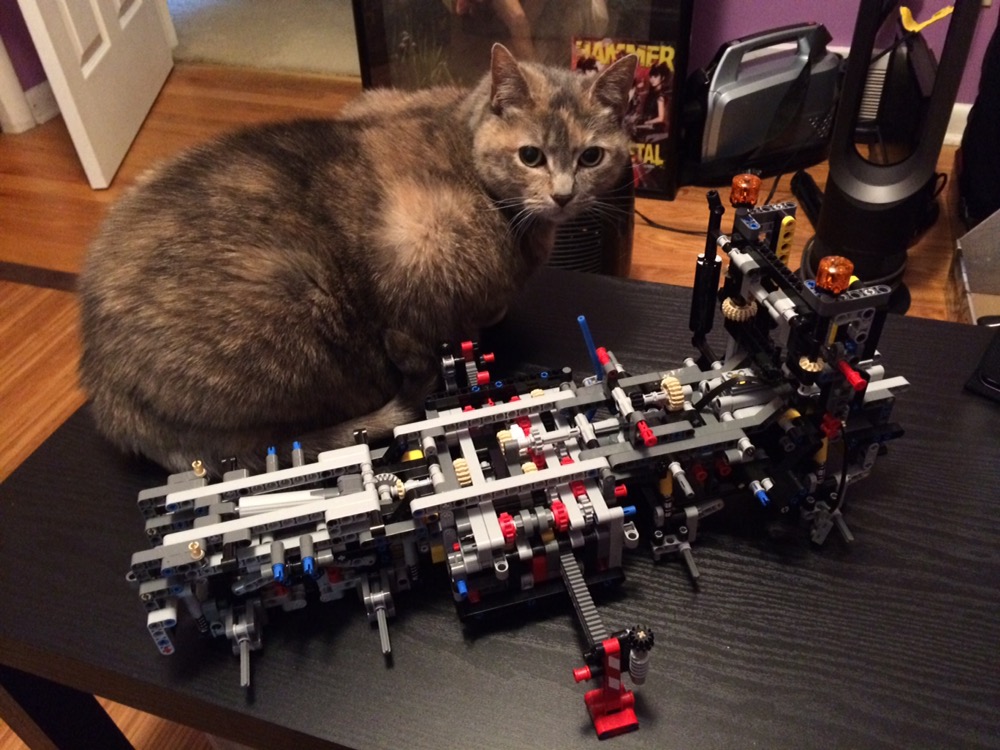

It’s also quite large. Here is the complete chassis (sans wheels) shown next to a rather large house at for scale:

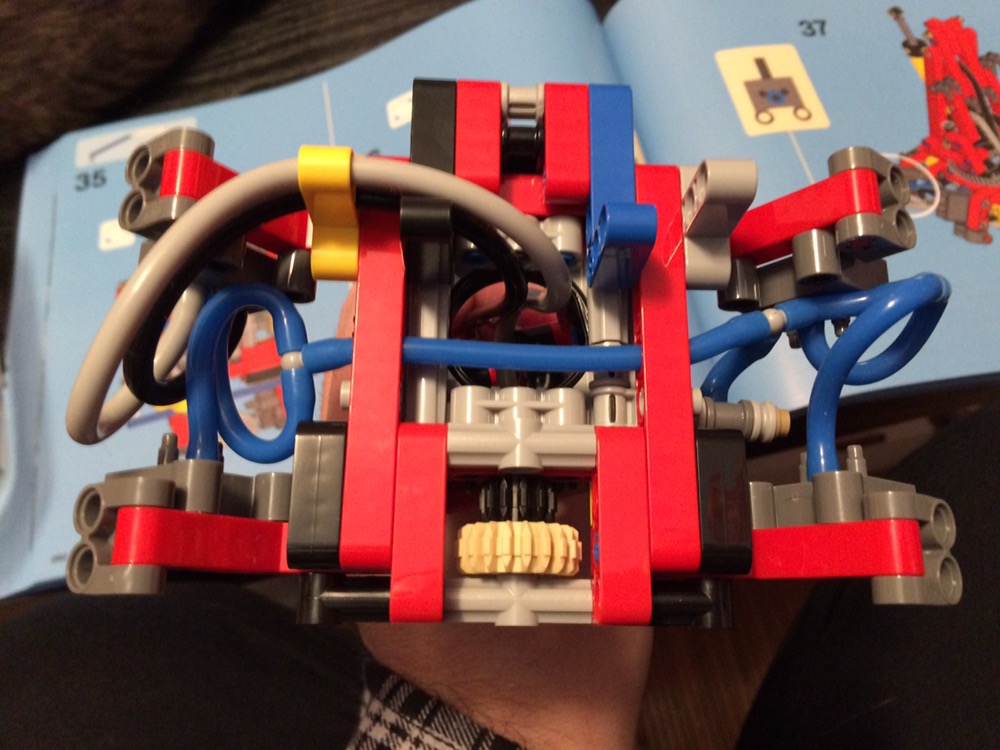

The pneumatic system is even more complicated, and we’re not trivial to assemble! Many times I thought I’d attached the wrong hose to the wrong nozzle, or feared that once I’d finished it wouldn’t work and I’d have to take it apart. For this kit, that’d be a nightmare!

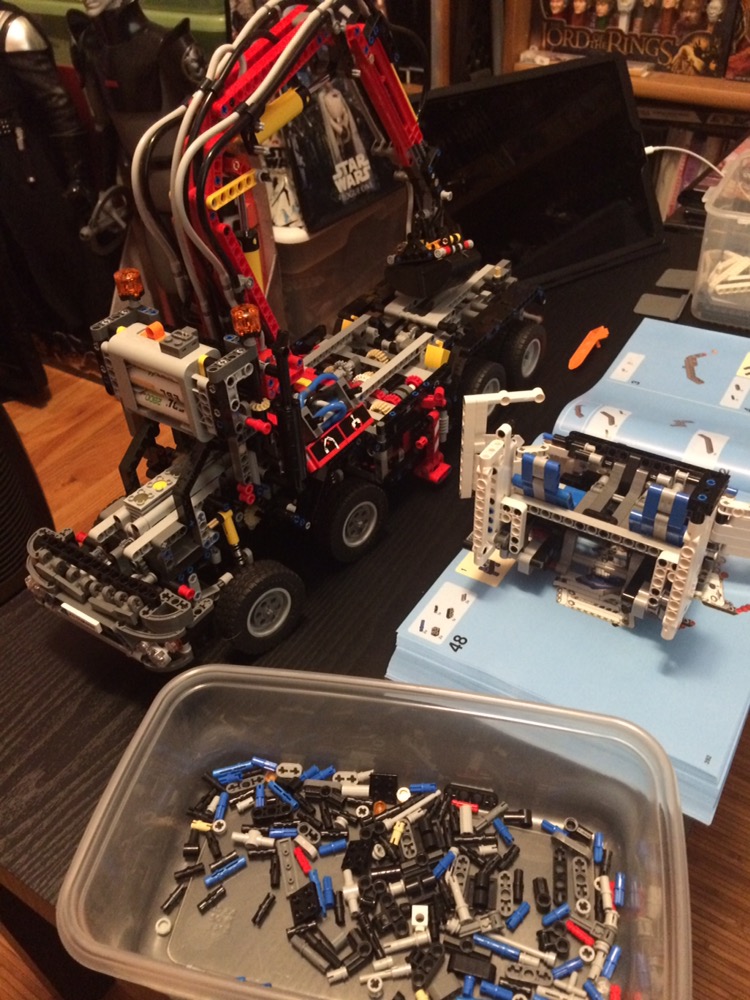

This is a real pneumatic system, which means the kit includes an electric pump that pushes air through these tubes to power pistons. It’s amazing just how much functionality they’ve worked in (four pistons and dozens of tubes) and how the kit is designed to fit all this in the crane itself. Here’s the truck 75% finished, only needing the cosmetic parts added (the cab and bed). Until this point, I’d been working for maybe 6 or 7 hours.

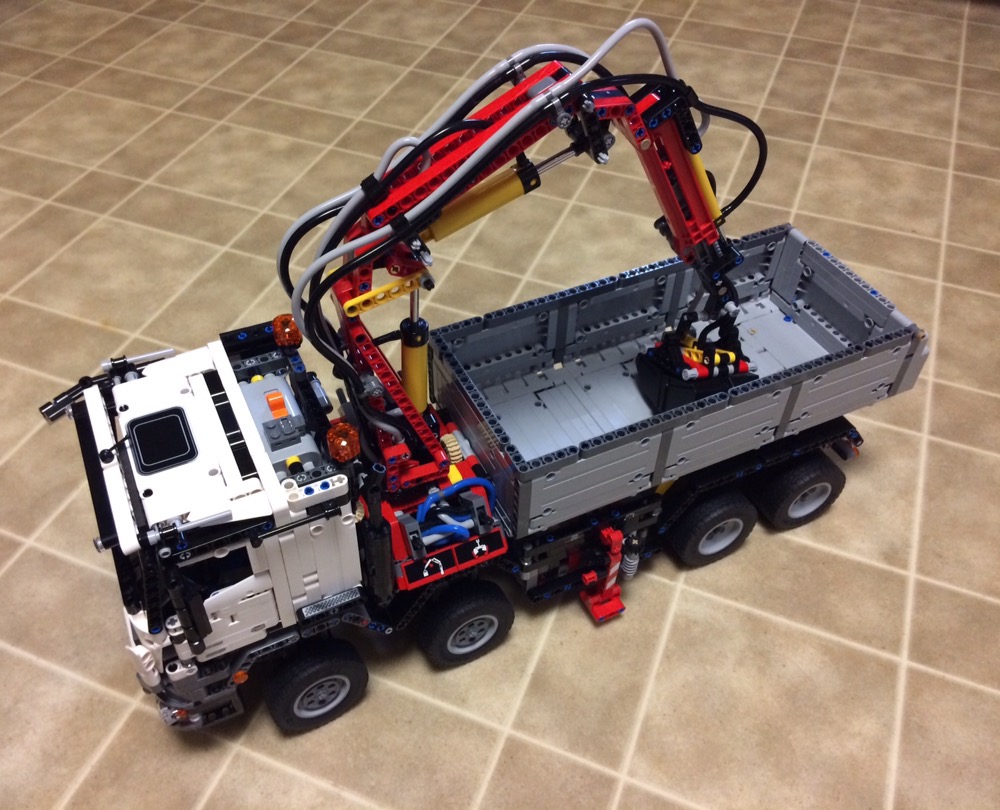

The remaining sections were easy by comparison, but that’s not to say they were simple. The mechanism to tilt the can forward was particularly nice. Here’s the finished kit in ‘road ready’ mode:

And here it is with the supports out, bed up and crane functioning:

All the functions you see above are controlled by the motor and switching system (via the astonishing gearing). I was very relieved it all worked first go 🙂

It’s a beautiful, massive, complex (and yes expensive) kit and was enormously fun to put together. Highly recommended 🙂

Ace job!

No video?

As it turns out I did record a video of the gearing but then deleted it 🙂

That is a great feat. It looks wonderful. Do you leave it on a shelf/table for awhile ? It is good that you still do Lego.