It’s time for the portrait contest results. If you’ve forgotten, the first half can be seen here. After the first five topics, Bernard was ahead 3-2!

The contest has now concluded. Let’s see how the judges voted on the remaining five…

Queen Elizabeth II

This was Lakshmi’s choice, and it was a subject I had considered selecting myself. Bernard’s is to the left, mine on the right. I went with a young Queen from 1952 and was quite proud of the texturing I got on her hair and the metallic look of the crown achieved only using a grey marker.

But… the judges apparently forgot the young Queen, and Bernard’s win of 3.5 to 1.5 (one judge gave a tie) was accompanied with some comments that only his pic looked like the Queen! Did these people forget the Queen’s coronation was almost 70 years ago?!? Lesson learned: create contemporary portraits only 🙂

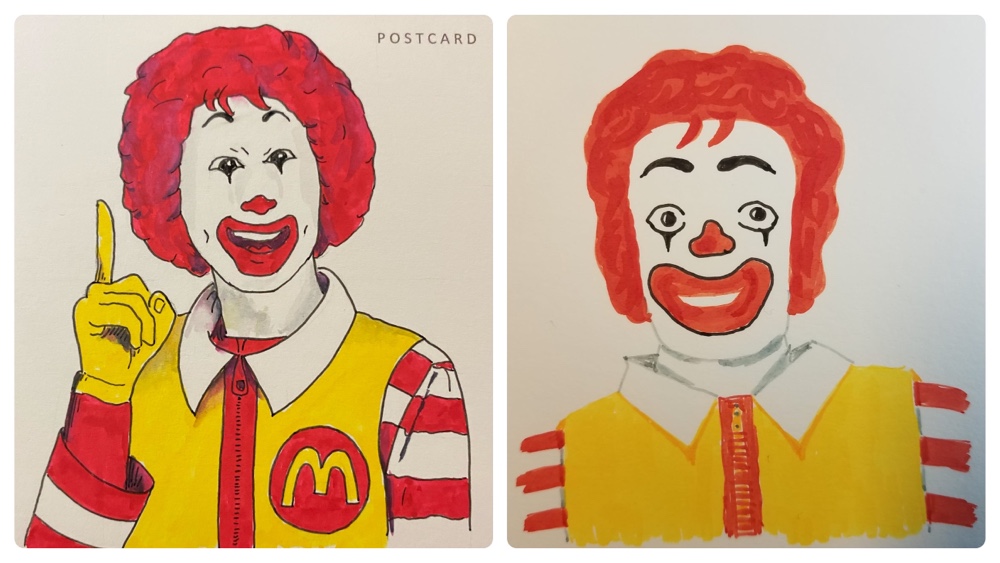

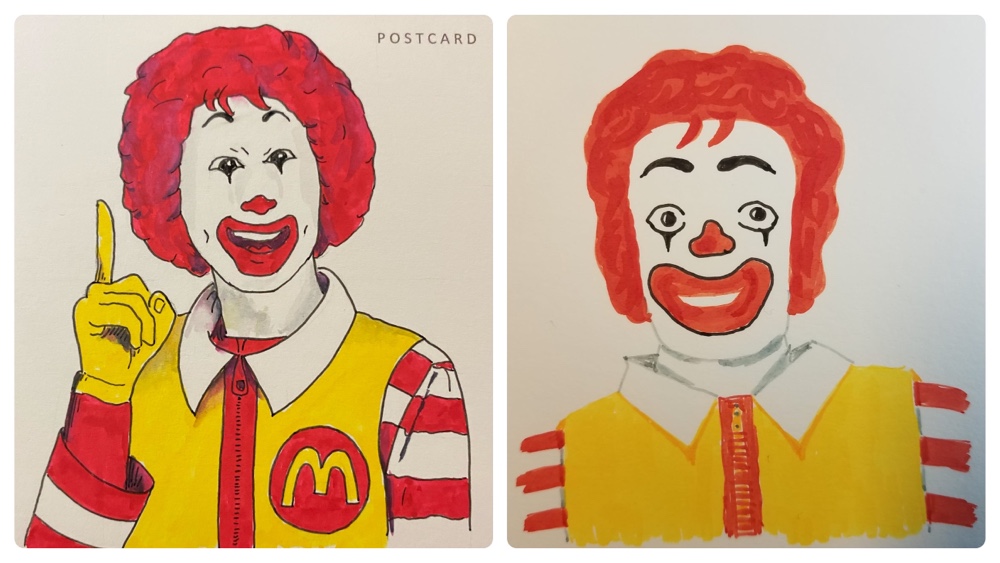

Ronald McDonald

The famous clown (he is a real person isn’t he?) was my next pic. This was a risky one since there’s not many variations of his look but… Bernard’s pic (on the right)… well I’ll quote a judge here: “Do I really have to say which one is best?”

I won this one 5-0, which was timely since Bernard’s lead had become significant. After 7 subjects, the score was Bernard 4, me 3.

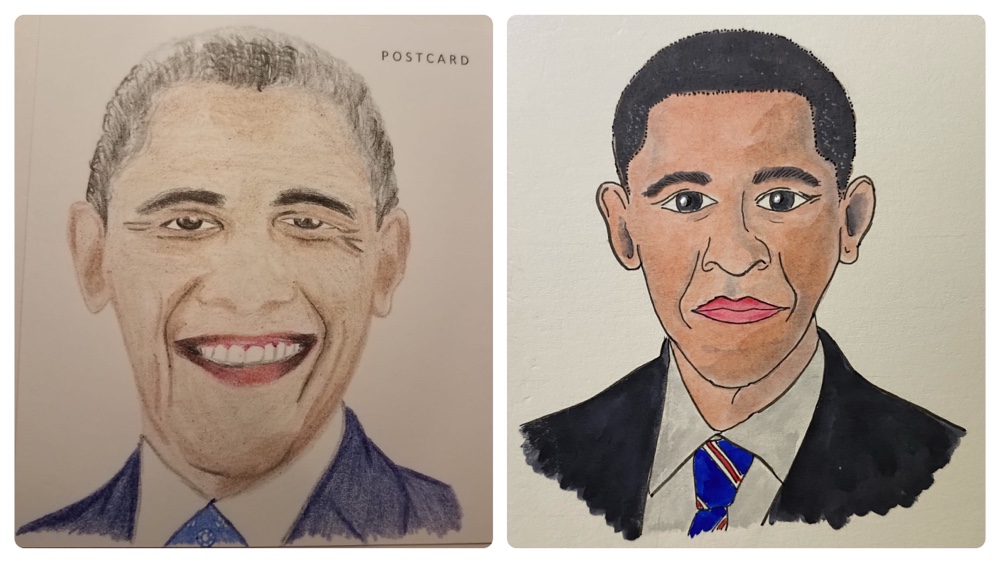

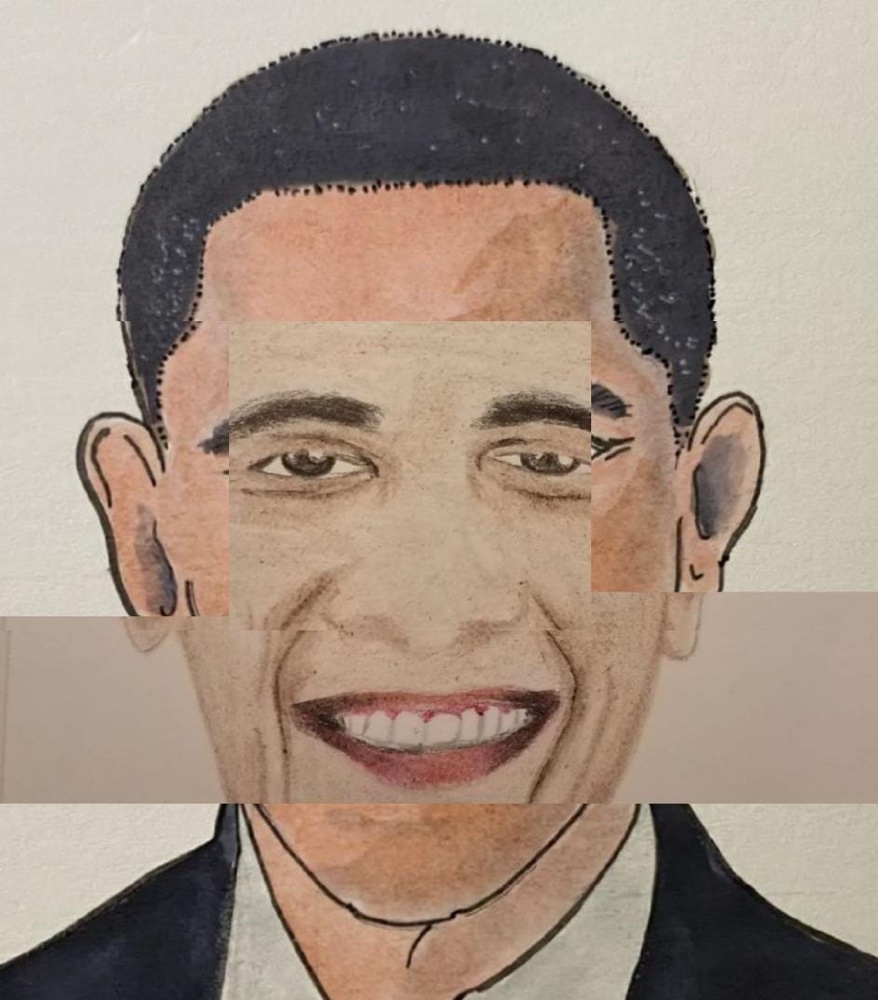

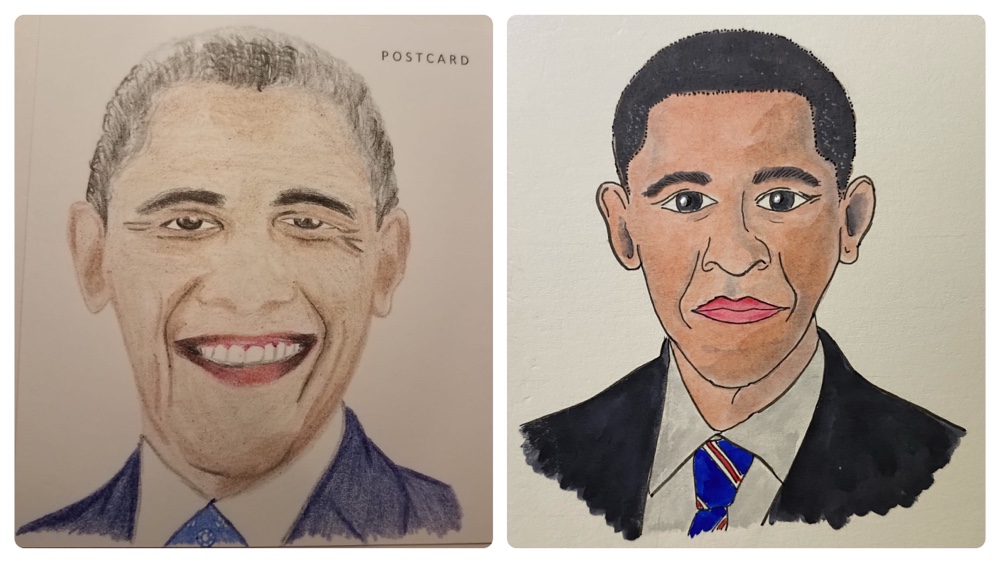

Barrack Obama

This was Bernard’s choice, and it was an obvious one I had been avoiding since I knew I didn’t have the right markers for his skin tone! He’s also a very handsome man with a strongly symmetric face, which means it would be very easy to create a portrait that didn’t look like him. But Obama it was, and I did my best!

Bernard’s is on the left, and mine on the right. The judges commented on the difficulty of judging this one, and ultimately gave me the win (3.5 to 1.5, with another tied judge) because Bernard’s “looks too old” or “has a weird chin“! One judge commented that neither looked like Obama. Regardless, the contest was now tied!

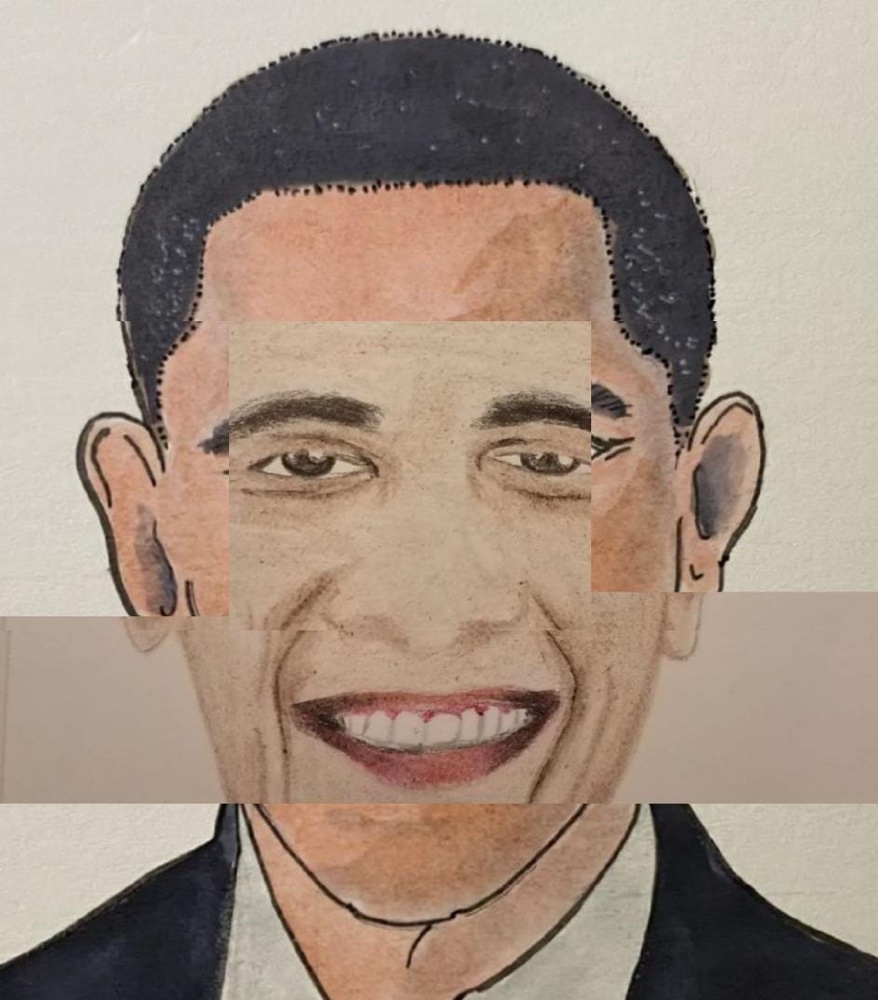

At this point I was making the observation that Bernard, on average, was strong with faces but weak with heads and hair, whereas I was the latter. Look at all the entries and see if you agree! One judge who is an artistic prodigy herself (JK) created this composite Obama from both our portraits to illustrate our respected strengths:

It looks more like him than either of ours doesn’t it?!?

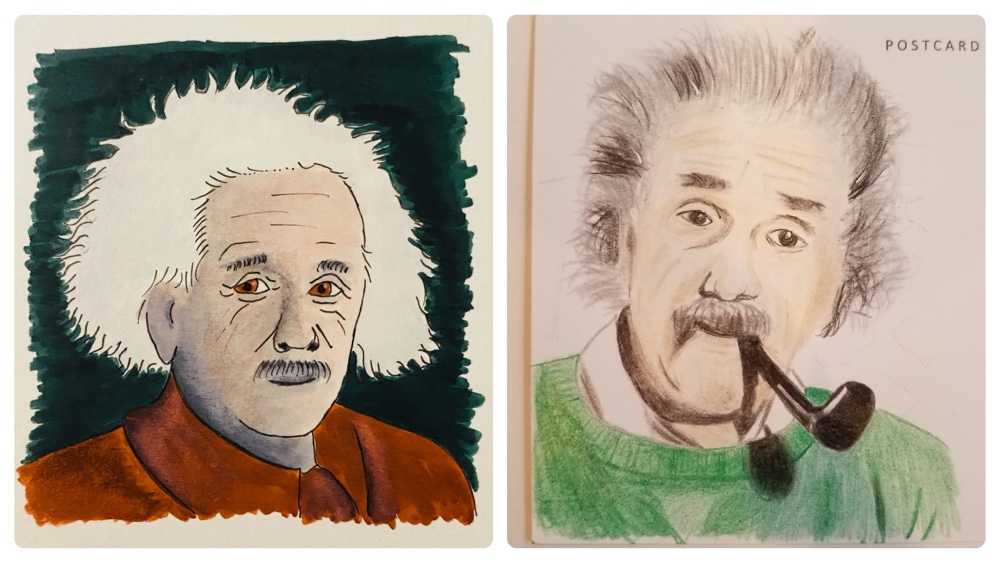

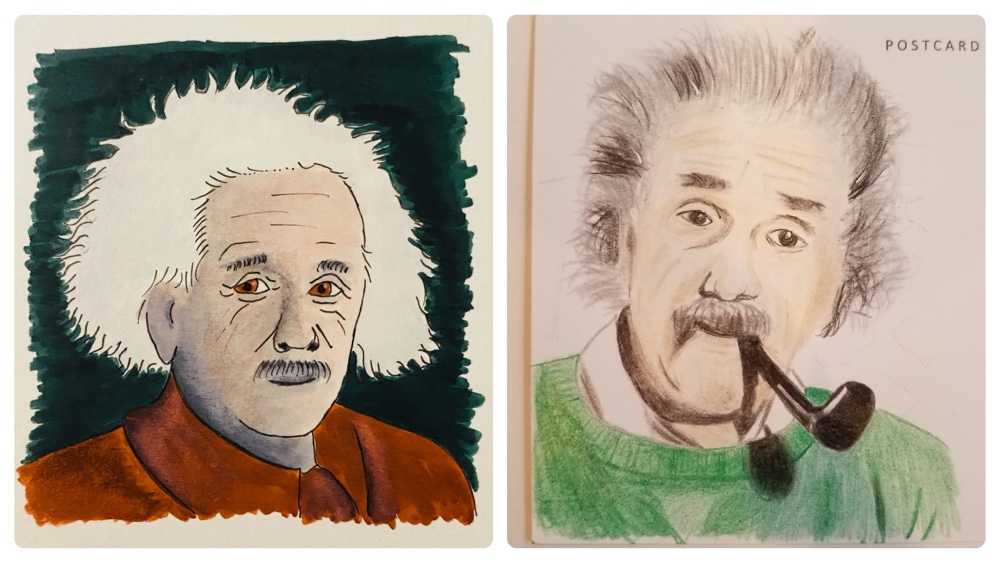

Albert Einstein

My final choice was a bad one. I should have chosen Gene Simmons, or David Bowie (which I deferred since I assumed he would be Bernard’s last). But for some weird reason I went with Einstein, and he was a real challenge to draw.

Mine is on the left, Bernard’s on the right. The judges gave Bernard the win in another 3.5 to 1.5 split, although the comments weirdly praised mine more (one said “Your hair and shading is better but I choose right“)! By now I had gotten used to the arbitrary decisions of the judges, and even though I question whether Bernard’s actually looks like Einstein I concede mine was weaker and expected a greater blowout in the scores.

Nine subjects completed and the score is Bernard has 5 wins over my 4. I had to win the last one to tie!

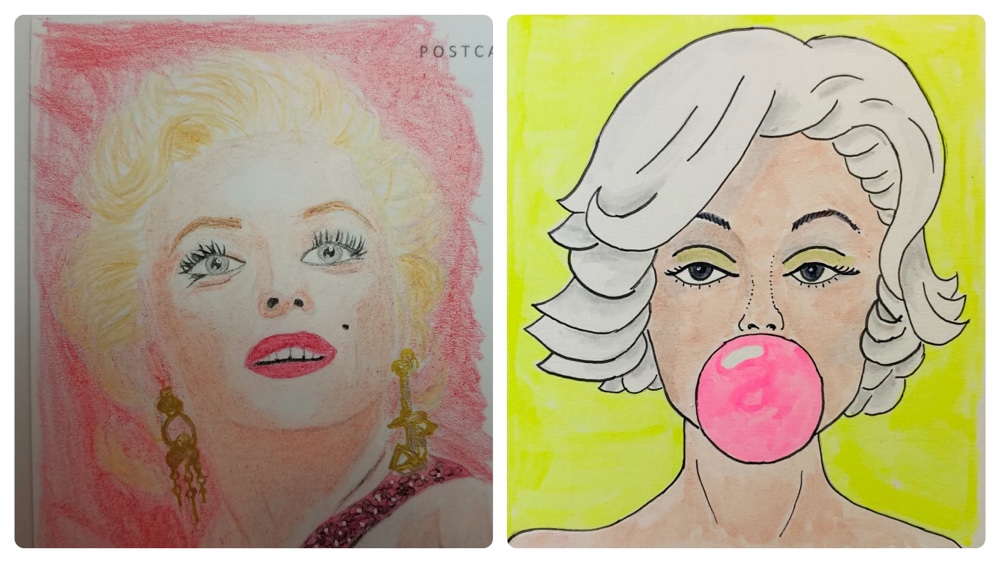

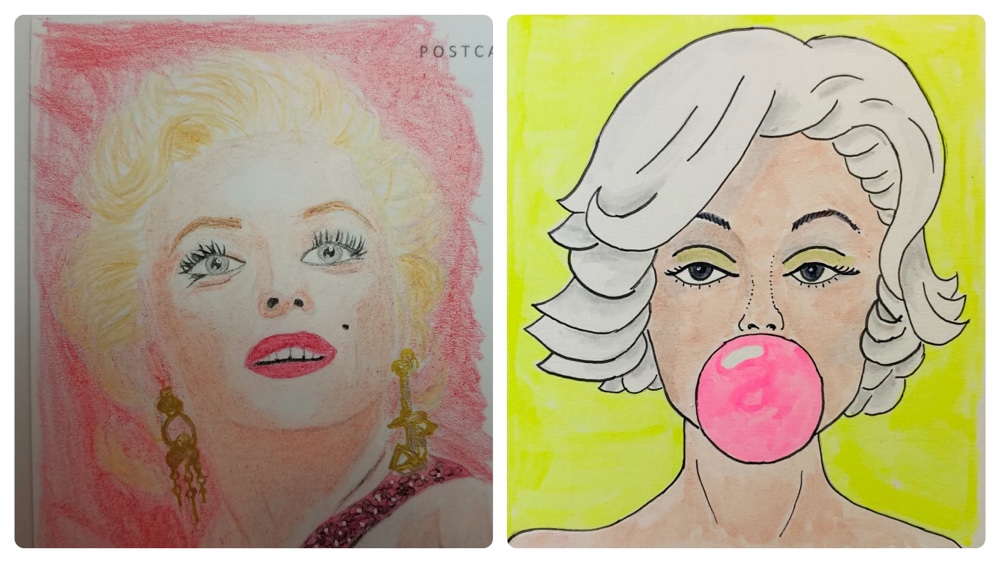

Marilyn Monroe

Bernard’s final choice was not Bowie. Instead, surprisingly, he chose Marilyn! And she was easily the hardest of the entire contest. This was magnified by the pressure on me to win.

My entry was the right, Bernard’s the left. He went with realism, me with a stylistic approach. The only problem: neither of them look like Marilyn Monroe! Four of the five judges said this, and commented how their decision was therefore based on artistic style. Two judges (and myself) commented how Bernard’s strongly resembled someone other than Marilyn (although we can’t quite place who), and two admired the bold colours of my piece.

Perhaps unsurprisingly considering these responses, the vote was a complete tie: 2.5 points each! The first tie in the contest was the last entry, and both our non-Marilyns were deemed equal 🙂

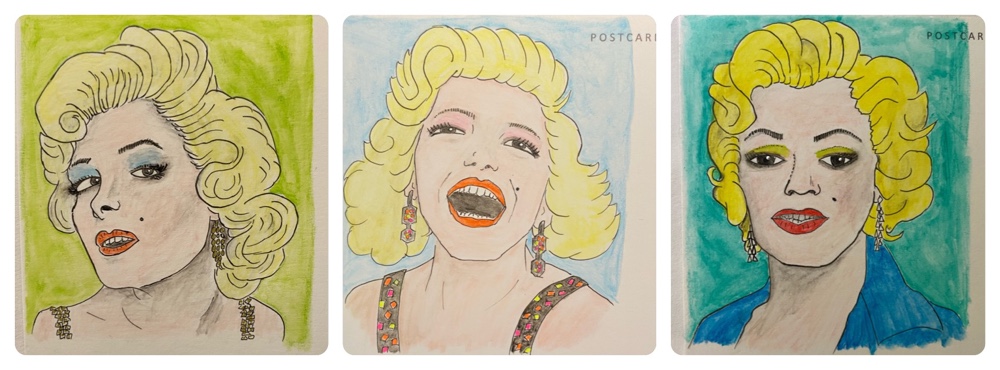

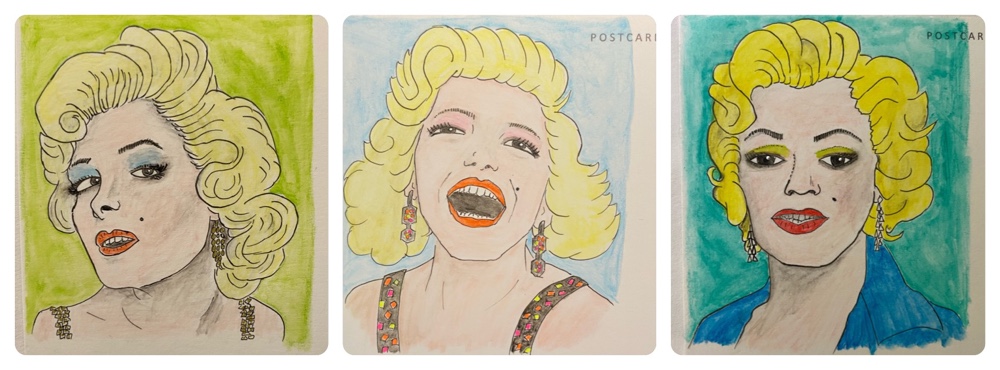

Incidentally I can now reveal that I actually made four Marilyn’s, rejecting each of them until I found one I liked. I knew my stylistic choice would work against the judges, but I greatly preferred it to the previous three, which were these:

I wonder how the judges would have liked the above?

Final Results!

Ten portraits done and judged. Fifty individual votes! It’s time for the results. And they are…

Bernard won, with 5.5 wins to my 4.5!

Looking at total points, of the 50 available, the final tally was Bernard 26.5 to my 23.5. That means that ultimately the final decision came down to only 1.5 votes out of 50! That’s extremely close 🙂

Looking back at all the portraits now, it’s obvious that our skills increased as the contest went on, and many times I felt I was presenting the judges with a difficult choice! Alas they were only human; it’s obvious Bernard’s Elvis win was a flagrant mockery of the (then) rules and my Queen was much better than his. But at the same time he claims his Obama was the better and (I suspect) will say the same about his Margot Robbie Marilyn.

I’m packing up Bernard’s prize right now – which is a quality item indeed – and wondering if we’ll ever do this again. And if we do, what we should draw. Any ideas?